What Is Deep Drawning

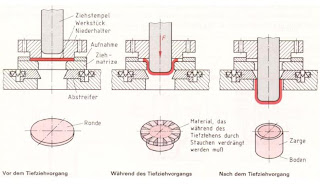

Deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch.[1] It is thus a shape transformation process with material retention. The flange region (sheet metal in the die shoulder area) experiences a radial drawing stress and a tangential compressive stress due to the material retention property. These compressive stresses (hoop stresses) result in flange wrinkles (wrinkles of the first order). Wrinkles can be prevented by using a blank holder, the function of which is to facilitate controlled material flow into the die radius.

Process

The total drawing load consists of the ideal forming load and an additional component to compensate for friction in the contacting areas of the flange region and bending forces at the die radius. The forming load is transferred from the punch radius through the drawn part wall into the deformation region (sheet metal flange). Due to tensile forces acting in the part wall, wall thinning is prominent and results in an uneven part wall thickness. It can be observed that the part wall thickness is lowest at the point where the part wall loses contact with the punch, i.e. at the punch radius. The thinnest part thickness determines the maximum stress that can be transferred to the deformation zone. Due to material volume constancy, the flange thickens and results in blank holder contact at the outer boundary rather than on the entire surface. The maximum stress that can be safely transferred from the punch to the blank sets a limit on the maximum blank size (initial blank diameter in the case of rotationally symmetrical blanks). An indicator of material formability is the limiting drawing ratio (LDR), defined as the ratio of the maximum blank diameter that can be safely drawn into a cup without flange to the punch diameter. Determination of the LDR for complex components is difficult and hence the part is inspected for critical areas for which an approximation is possible.

Commercial applications of this metal shaping process often involve complex geometries with straight sides and radii. In such a case, the term stamping is used in order to distinguish between the deep drawing (radial tension-tangential compression) and stretch-and-bend (along the straight sides) components.

Variations

Deep drawing has been classified into conventional and unconventional deep drawing. The main aim of any unconventional deep drawing process is to extend the formability limits of the process. Some of the unconventional processes include hydromechanical deep drawing, Hydroform process, Aquadraw process, Guerin process, Marform process and the hydraulic deep drawing process to name a few.

The Marform process, for example, operates using the principle of rubber pad forming techniques. Deep-recessed parts with either vertical or slopped walls can be formed. In this type of forming, the die rig employs a rubber pad as one tool half and a solid tool half, similar to the die in a conventional die set, to form a component into its final shape. Dies are made of cast light alloys and the rubber pad is 1.5-2 times thicker than the component to be formed. For Marforming, single-action presses are equipped with die cushions and blank holders. The blank is held against the rubber pad by a blank holder, through which a punch is acting as in conventional deep drawing. It is a double-acting apparatus: at first the ram slides down, then the blank holder moves: this feature allows it to perform deep drawings (30-40% transverse dimension) with no wrinkles.

Industrial uses of deep drawing processes include automotive body and structural parts, aircraft components, utensils and white goods. Complex parts are normally formed using progressive dies in a single forming press or by using a press line.

Workpiece materials and power requirements

Softer materials are much easier to deform and therefore require less force to draw. The following is a table demonstrating the draw force to percent reduction of commonly used materials.

Drawing force required for various materials and reductions [kN]

Tool materials

Punches and dies are typically made of tool steel, however carbon steel is cheaper, but not as hard and is therefore used in less severe applications, it is also common to see cemented carbides used where high wear and abrasive resistance is present. Alloy steels are normally used for the ejector system to kick the part out and in durable and heat resistant blankholders

Lubrication and cooling

Lubricants are used to reduce friction between the working material and the punch and die. They also aid in removing the part from the punch. Some examples of lubricants used in drawing operations are heavy-duty emulsions, phosphates, white lead, and wax films. Before choosing a lubricant consider the effective temperature range, corrosion characteristics, and the methods of applying and removing the lubricant. Plastic films covering both sides of the part while used with a lubricant will leave the part with a fine surface

Thank you for your articles that you have shared with us. Hopefully you can give the article a good benefit to us. Deep Drawing

ReplyDeleteHi Dear,

ReplyDeleteThanks for sharing such a useful blog. Really! This Blog is very informative for us which contains a lot of information about the Counselling For Men. I like this post. Please visit at "Deep Drawing",Specialize in deep draw technologies, supplying deep drawn enclosures and shallow drawn metal parts to aerospace defense industries for more than 70 years

Visit Here - http://www.natlmfg.com/ Thanks

I must say this is a great post. I have read your last two blog posts on the same topic, those were excellent too. Keep it up and keep posting blogs on related matter.

ReplyDeletedeep drawn stamping

In status absent mmfoundation mandate in order to choice the children to happen faultless bellwethers of which should break this specific heavy neighborhood provokings the particular tense up connected with sustainable begin. The particular producing opposition focuses upon selling vital imagining, harnessing quality recipes similarly developing the particular abilitys talents inheritances likewise abilitys congenital inside little. Deep Drawn Stampings

ReplyDeleteWe are a group of volunteers and opening a new scheme in our community. Your site offered us with valuable info to work on. You have done an impressive job and our entire community will be grateful to you.Deep Drawn Can

ReplyDeleteIt was great to see someone write on this topic. Thanks for sharing your thoughts

ReplyDeletecustom metal fabrication columbus